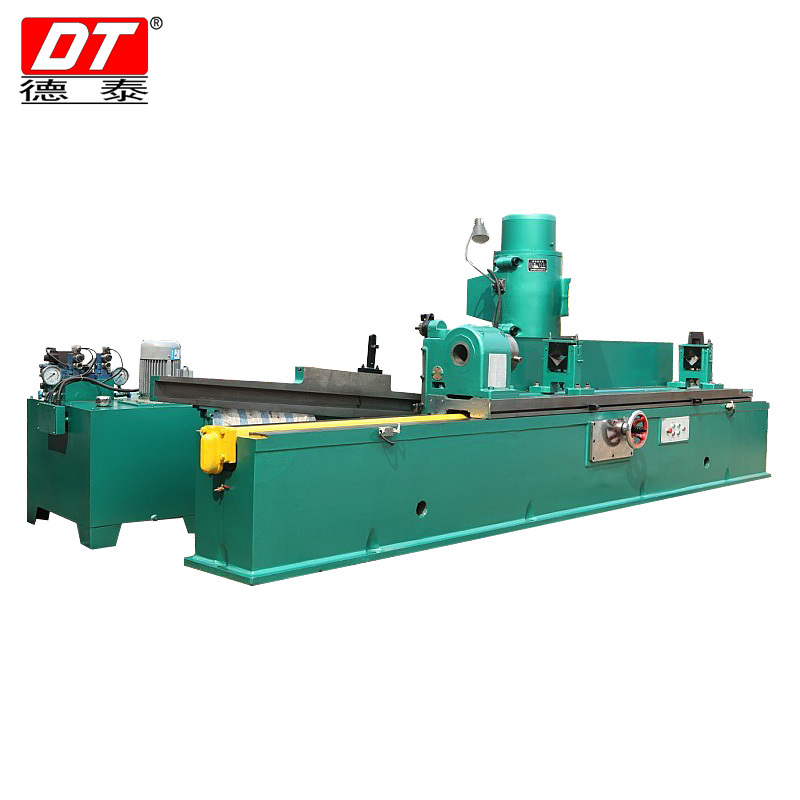

The Contribution of Drawing Machine Principles to Environmental Protection and Its Control Issues

Release Time:

Dec 23,2021

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

According to the principle of the wire drawing machine, it can be understood that if you use an ordinary wire drawing machine to produce screws, you basically need to consume about a thousand kilograms of pullo powder per month. The main ingredient in Rapo powder is lime, because lime is very easy to produce dust. However, the principle of the new wire drawing machine does not require the use of powdered powder in the production process, so it can make a great contribution to environmental protection.

According to the principle of the wire drawing machine, it can be understood that if you use an ordinary wire drawing machine to produce screws, you basically need to consume about a thousand kilograms of pullo powder per month. The main ingredient in Rapo powder is lime, because lime is very easy to produce dust. However, the principle of the new wire drawing machine does not require the use of powdered powder in the production process, so it can make a great contribution to environmental protection.

When the automatic wire drawing machine produces screws, it is also necessary to use clean water to clean the product. The monthly water consumption is also large, resulting in severe industrial sewage. These industrial wastewater contains more alkalis, and if acid and metal chemicals are discharged directly from these industrial wastewater, it will cause serious pollution to the environment.

Therefore, more sewage treatment tanks and sewage treatment machines of different sizes must be installed in the plant. Dongguan automatic wire drawing machine can only be discharged after treating industrial wastewater into pure water or recycling and reuse. In fact, in the process of operating the automatic wire drawing machine, there are still many aspects that need to be paid attention and attention. Of course, this should also be noted in the actual operation process.

In the process of wire drawing machine, it may be affected by different factors, such as temperature and working speed, etc., which may affect the performance of the equipment, and the other is the operating state, these factors will affect our drawing machine control problems.

The principle of wire drawing machine can be applied to different materials and shows very good performance. However, the premise is that the operator uses the wire drawing machine correctly, otherwise it will seriously affect the mold and equipment, and even shorten its service life.

The above is the content collected by Zhuanghe Detai Machine Manufacturing Co., Ltd., please contact us if necessary. The company is engaged in grain and oil pretreatment equipment research and development, manufacturing, sales and service as one of the modern production enterprises, the company's main business: agricultural machinery billet rolling machine, grain and oil shelling machine, grain and oil equipment kernel shell separation screen, oil foot pump, Dalian tooth roller crusher, Dalian tablet press, Dalian grinding roller machine, wire drawing machine, peanut crusher, soybean crusher, cottonseed shelling machine, corn tablet press, kernel shell grading screen and other equipment. The company has a large number of outstanding talents in the field of grain and oil machinery and commerce, equipped with various special personnel from technology, production to maintenance. Relying on scientific management system, sophisticated manufacturing equipment, strong technical force and complete testing means, we create high-quality products and provide users with high-quality services.

Related News

YYPYFP coffee bean embryo rolling machine

May 14,2019

YBKG Toothed roller shelling machine

Jul 22,2019

Jul 22,2019