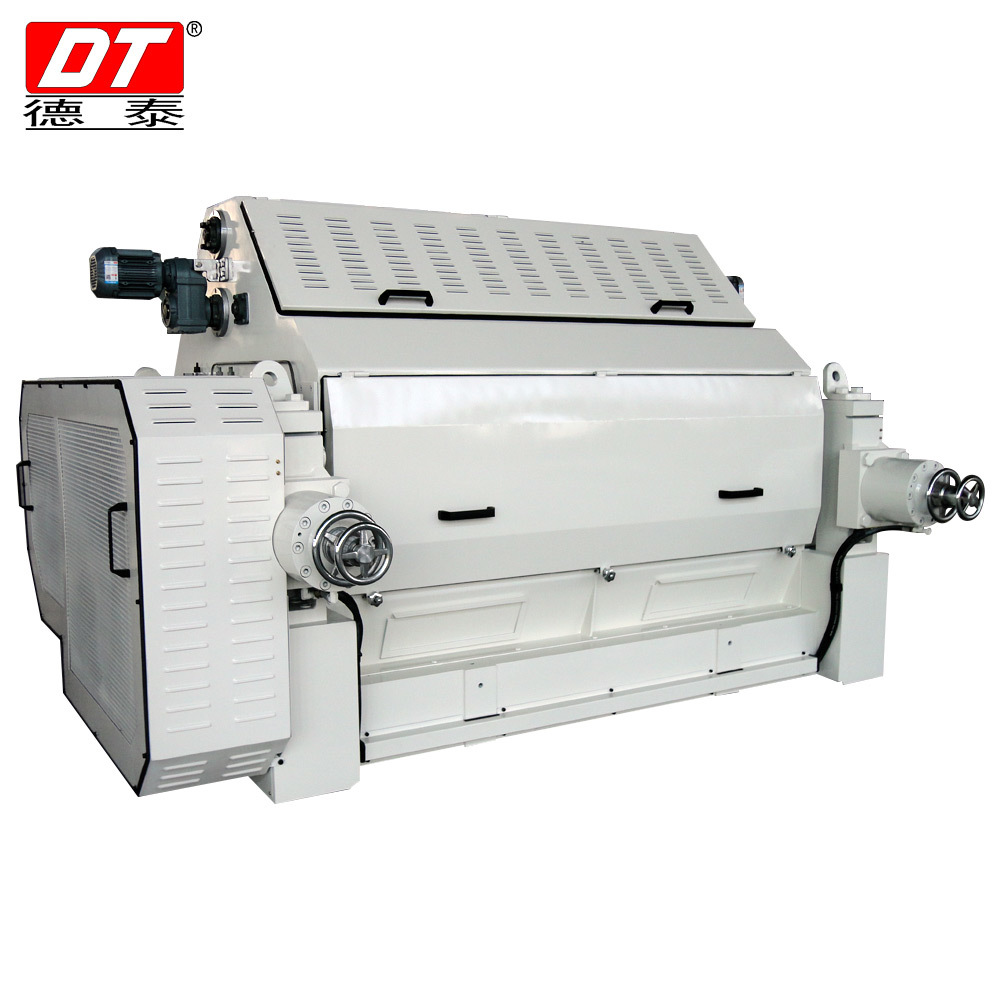

Manufacturer of the embryo rolling machine: Structure description of the embryo rolling machine

Release Time:

Nov 24,2020

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

The mill produced by the mill manufacturer is mainly made of two or several rolls (high nickel-chromium-molybdenum alloy) rotating in opposite directions. When the oil (soybeans, peanuts, cottonseed, etc.) passes through the middle of the two rollers, the embryo is formed by an instantaneous extrusion force. Crude oil is pushed out, then refined and leached to form a finished cooking oil. It is a typical extrusion equipment.

The mill produced by the mill manufacturer is mainly made of two or several rolls (high nickel-chromium-molybdenum alloy) rotating in opposite directions. When the oil (soybeans, peanuts, cottonseed, etc.) passes through the middle of the two rollers, the embryo is formed by an instantaneous extrusion force. Crude oil is pushed out, then refined and leached to form a finished cooking oil. It is a typical extrusion equipment.

Detai recommends the structure description of the rolling mill

1. The rolls of the rolling machine are divided into fixed rolls and mobile rolls. The rolls are centrifugally cast and cold-loaded and have a hard nickel-chromium-molybdenum alloy working surface. The grease is obtained by the opposite rotation of a pair of rollers, and the thickness of the chips is controlled by the set roll pressure and roll feed speed. There is a pressure cylinder between the moving roller and the fixed roller, and the uniform rolling pressure between the two rolls can be changed by adjusting the pressure of the pump station. The rolls are installed horizontally on the base of the finishing mill by means of a tile base.

2. The rollers rotate in SKF self-aligning double row cylindrical roller bearings fixed at both ends, and the bearings are wrapped in a tightly sealed bearing oil chamber. A centralized lubrication system on the left and right sides of the mill ensures the lubrication of the bearings.

3. The bearing pressure cylinder is installed on the pad on both sides of the roller. Provides the necessary adjustment pressure to keep the roll gap to the ideal standard.

4. There are two types of bases of the rolling mill: casting and welding, all of which are treated to relieve internal stress and finish. A roller tile holder is installed on it.

5. Feeding device, the gate is used to control the flow of petroleum raw materials between two rollers.

6. The magnetic separation device can prevent metal chips from entering the drum and damaging the reel, so it must be cleaned frequently.

The above is the content collected by Zhuanghe Detai Machine Manufacturing Co., Ltd., please contact us if necessary. The company is engaged in grain and oil pretreatment equipment research and development, manufacturing, sales and service as one of the modern production enterprises, the company's main business: agricultural machinery billet rolling machine, grain and oil shelling machine, grain and oil equipment kernel shell separation screen, oil foot pump, Dalian tooth roller crusher, Dalian tablet press, Dalian grinding roller machine, wire drawing machine, peanut crusher, soybean crusher, cottonseed shelling machine, corn tablet press, kernel shell grading screen and other equipment. The company has a large number of outstanding talents in the field of grain and oil machinery and commerce, equipped with various special personnel from technology, production to maintenance. Relying on scientific management system, sophisticated manufacturing equipment, strong technical force and complete testing methods, we create high-quality products and provide users with the best quality service.

Related News

YYPYFP coffee bean embryo rolling machine

May 14,2019

YBKG Toothed roller shelling machine

Jul 22,2019

Jul 22,2019