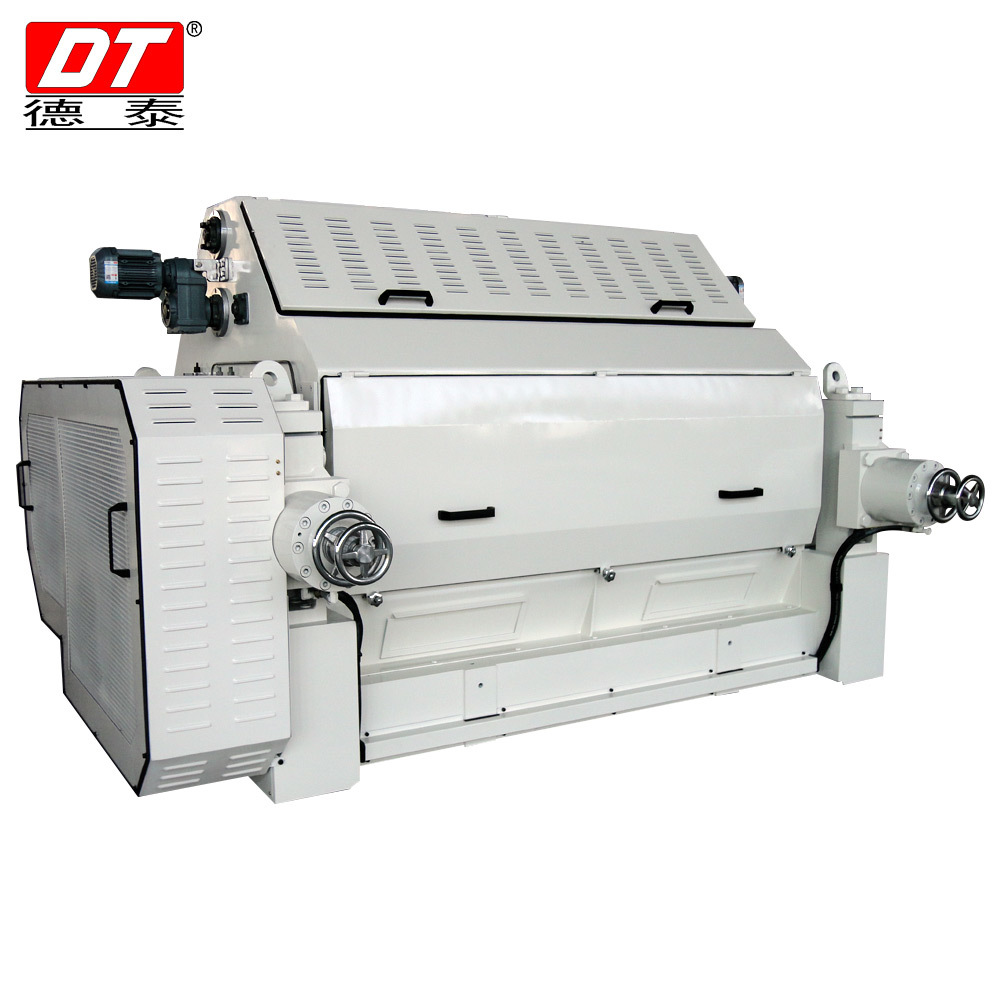

Wire drawing machine

Key

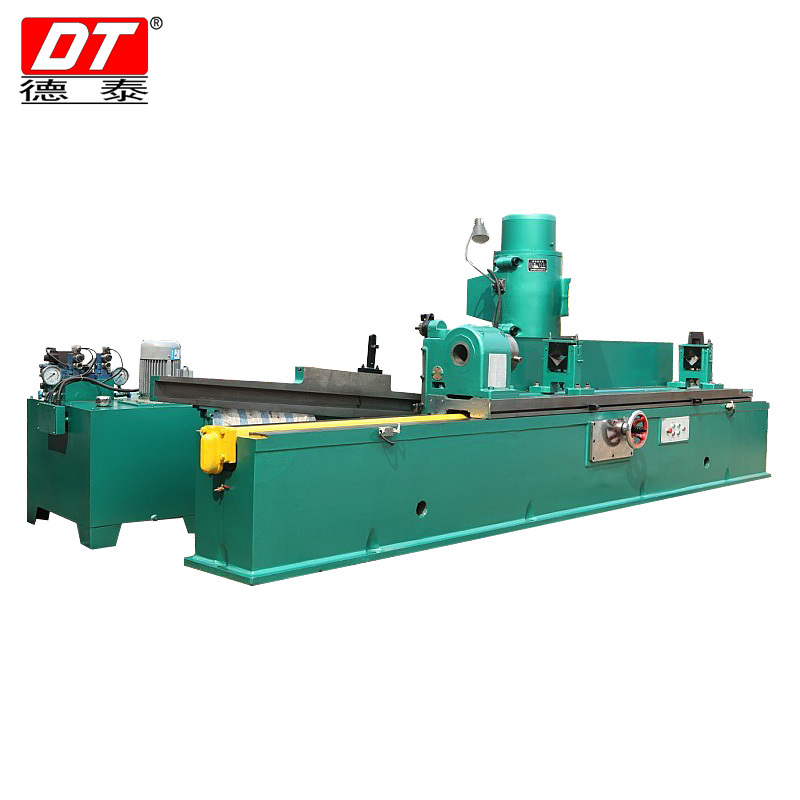

Rolling Mill Series, Crusher Series

Category

Wire drawing machine series

Product Details

The wire drawing machine process is a surface treatment technology for workpieces. A surface treatment method is to achieve a decorative effect by forming a line on the surface of the workpiece through a wire drawing machine. Since the wire drawing treatment on the surface can reflect the texture of the metal material, the automatic wire drawing machine has been adopted by more and more enterprises.

Control mode of wire drawing machine and power saving measures

Wire drawing machines are widely used in industry: machinery manufacturing, hardware processing, petrochemical, plastics, bamboo and wood products, wire and cable and other industries. The more mainstream control method is the constant tension automatic control system. The system consists entirely of a home control unit. Its structure is relatively compact, the cost is relatively low, and the operation is relatively stable and reliable. Many of the main drawbacks of the original machine control system were solved and the winding capacity for one disconnection could be greatly improved.

According to its working principle, we know that when the wire drawing machine works, there is a program that needs to be heated. When the barrel of the wire drawing machine is heated, it actually works using a heating ring. This way of working generates more electricity.

The heating process of the wire drawing machine is as follows: first the heating ring needs to be heated to the heated state, and then transferred to the barrel through the heating ring. This is the process of heat transfer. Therefore, a part of the heat will definitely not be used and wasted during this transfer process. Obviously, the wasted heat actually comes from electricity.

In addition to part of the heat loss during transfer, the surface of the heating ring will also come into contact with air. Therefore, the other part of the heat is absorbed by the air, which is also a waste of electricity. When the wire drawing machine is running, the heat transfer process in the heating coil alone loses about 40% of the electricity. It is conceivable that energy will be saved if the waste of electricity in this process can be effectively avoided.

In order to reduce power consumption, what needs to be done is to wrap a layer of insulation cotton on the surface of the wire drawing machine barrel, and then add an electromagnetic heating coil. When energized, the electromagnetic induction coil will generate electromagnetic induction and the barrel will automatically heat up. Insulating cotton prevents heat from being dissipated into the air and saves at least 30% of electricity.

Inqiury