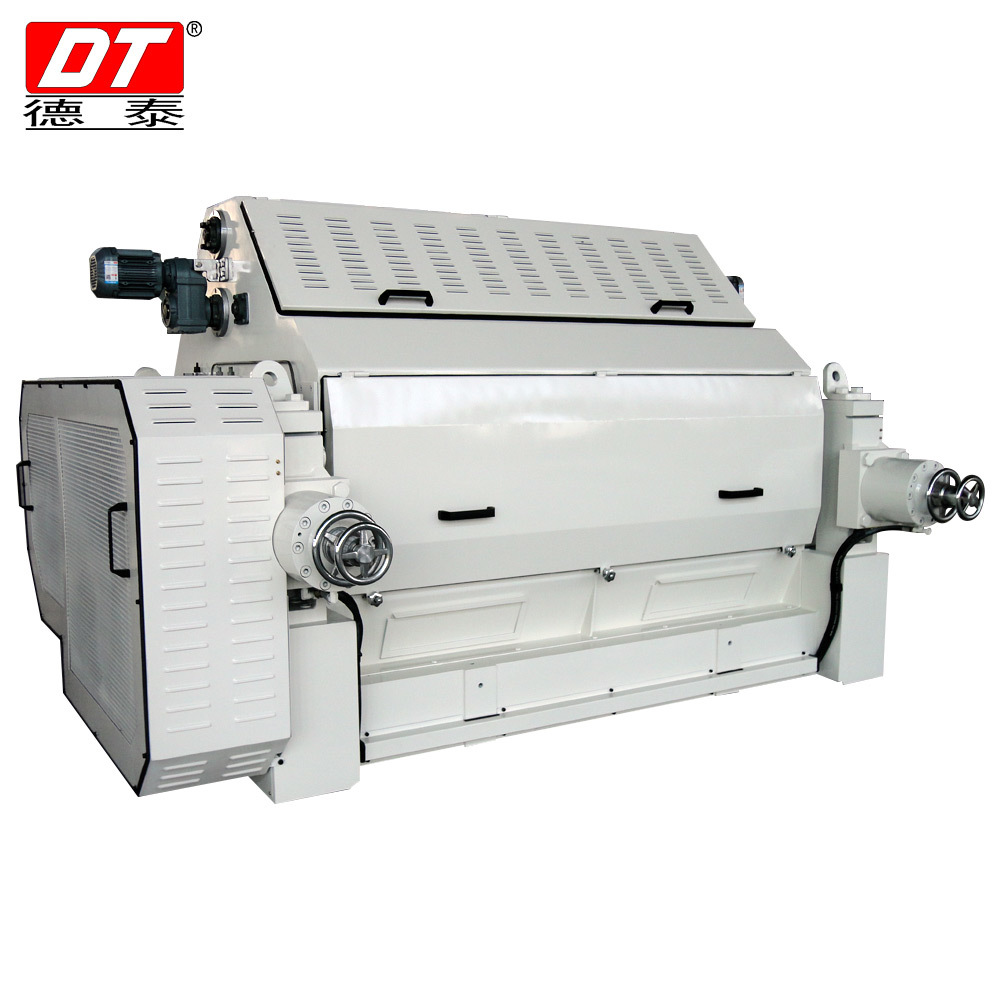

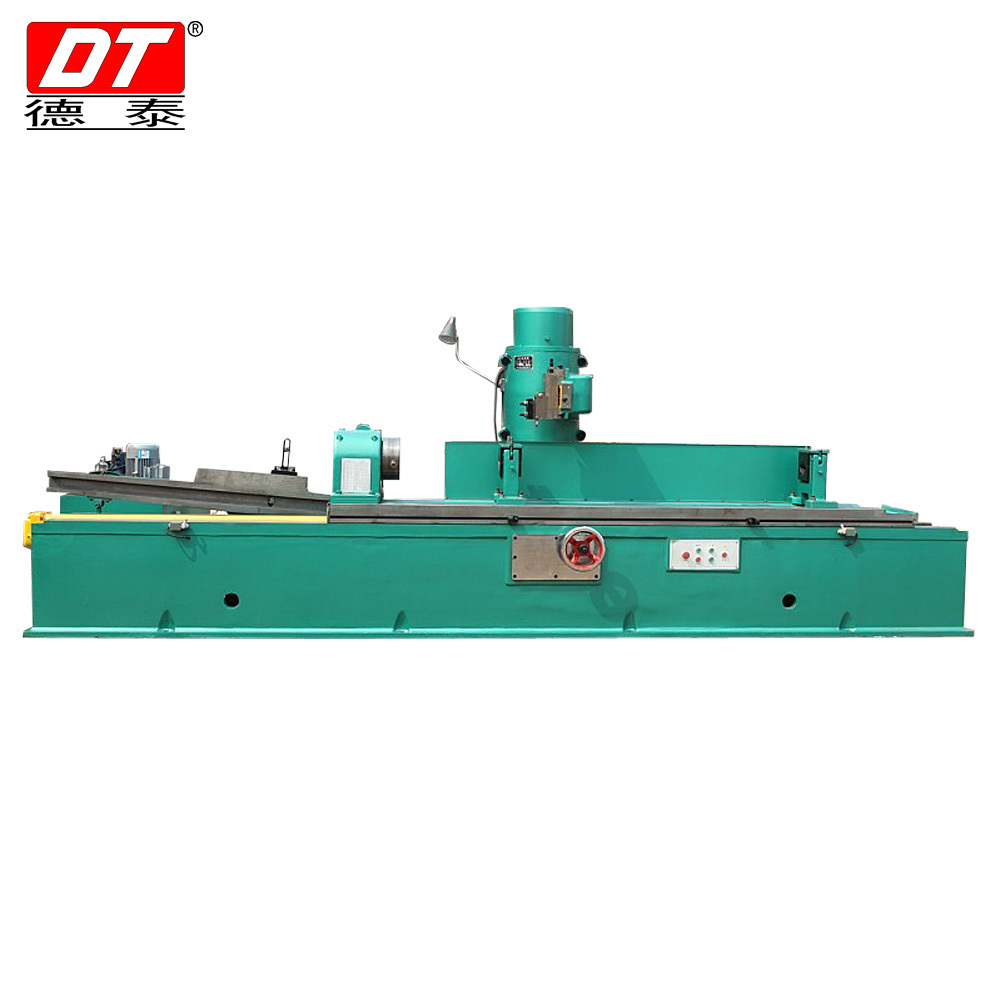

JYL220 Wire drawing machine

Key

Rolling Mill Series, Crusher Series

Category

Wire drawing machine series

Product Details

The JYL220 wire drawing machine is suitable for crushing, shelling or roller tooth drawing or dressing of flour rolls. It adopts the integral casting bed and workbench, which has stronger working capacity and reliability, and higher work efficiency; Independent hydraulic control unit, more convenient maintenance. Has independent intellectual property rights. (Patent No.: ZL201220181589.6)

Main technical parameters:

|

Before operating the wire drawing machine, the operator must carefully read the drawings and related technical data, and understand and master them. When machining, it is necessary to correctly select and confirm the drawing direction, drawing surface, etc., and operate according to the rules. It is also necessary to maintain the appearance of the workpiece to prevent it from being scratched and to avoid deterioration.

Products processed by wire drawing machines should be handled with care and should be maintained to avoid damaging the product. The exterior and surrounding environment of the equipment should be kept clean, tidy and hygienic; Air supply pipes, joints and abrasive belts should be inspected to see if they feel good to the touch and need to be adjusted; Drain the water from the air filter and smooth the housing.

In addition to daily maintenance, it is also necessary to check whether the tension of the wire drawing conveyor belt and the abrasive belt is suitable and whether it needs to be adjusted; Whether the wire drawing machine is operated correctly and safely to ensure that the wire drawing machine is always in good working condition.

Wire drawing machines are used for higher requirements of general plastic wire drawing machines. The whole system is more complex, and the control equipment requires coordination between various motors. The system is controlled using four servo motors, which fully satisfies the real-time interaction between data and servos, so as to realize real-time data exchange between each set of axes.

In the system view that requires fast interaction between motor shafts, in order to ensure the locality of the track siding according to the algorithm, the wires in the row need to be quickly considered. We also took full advantage of the servo internal firmware functions calculated by the drive itself. The autonomous motor travel line greatly saves the calculation of the direction of travel of the traditional plastic wire drawing machine control system, and then sends it to the driver to introduce a time delay to ensure that the delay of the line line passing through the robot is minimized.

Inqiury