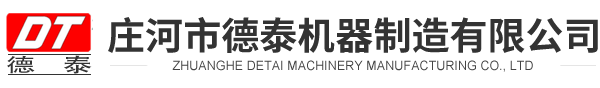

JMN Wire drawing machine

Key

Rolling Mill Series, Crusher Series

Category

Wire drawing machine series

Product Details

JMN wire drawing machines are suitable for crushing, shelling or roller tooth drawing or dressing of flour rolls. Its mechanical, electrical and hydraulic integration, stable and reliable working performance.

Main technical parameters:

|

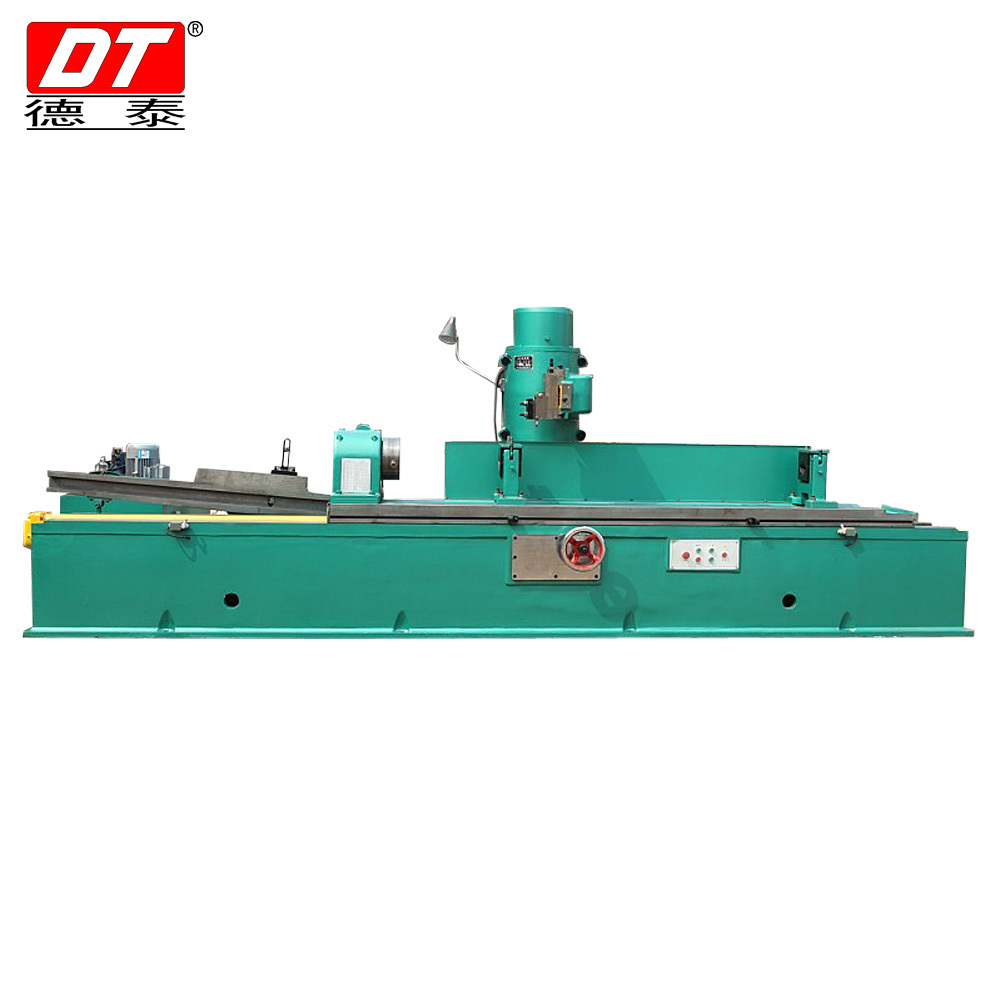

The wire drawing machine is used for ordinary plastic wire drawing machine with high requirements for wire drawing. The entire system is more complex, and the control equipment requires coordination between the various motors. There are many ways to heat the wire drawing machine, some use resistance wire heating, some use electromagnetic heating.

Among them, resistance wire heating is equivalent to heating using heat transfer. This is because the iron sheet is heated and the heat is transferred into the barrel. In this process, part of the heat is consumed on the way, while the other part is dissipated into the air, resulting in a waste of thermal energy, which is equivalent to the waste of electrical energy.

The function of electromagnetic heaters is to heat plastic machinery and save energy. It can completely replace the old resistance heater. The main purpose is to wrap a layer of thermal insulation cotton on the barrel, which can reduce heat consumption, and then wrap it on the insulation pad. One layer of electromagnetic heating coil. When the wire drawing machine is energized, the iron molecules in the barrel run relatively strongly, and the barrel generates heat. Therefore, this method is more energy-efficient and efficient than traditional methods. Changing from the conventional resistance type to the current electromagnetic heating type also saves about 30% of electrical energy.

Speed control is high on wire drawing machine systems, which can provide very precise and lubricated linear speeds. Four servo motors were selected for control, which satisfies real-time interaction between data and real-time data exchange between each set of axes.

In order to ensure the locality of the lateral lines of the trajectory according to the algorithm, it is necessary to quickly calculate the lines of the lines. The calculation of the drive itself, i.e. the wiring of the autonomous motor, greatly saves the line direction of the traditional wire drawing machine control system. After the calculation is sent to the drive due to the time delay, the guaranteed wire can minimize the delay through the manipulator.

Inqiury