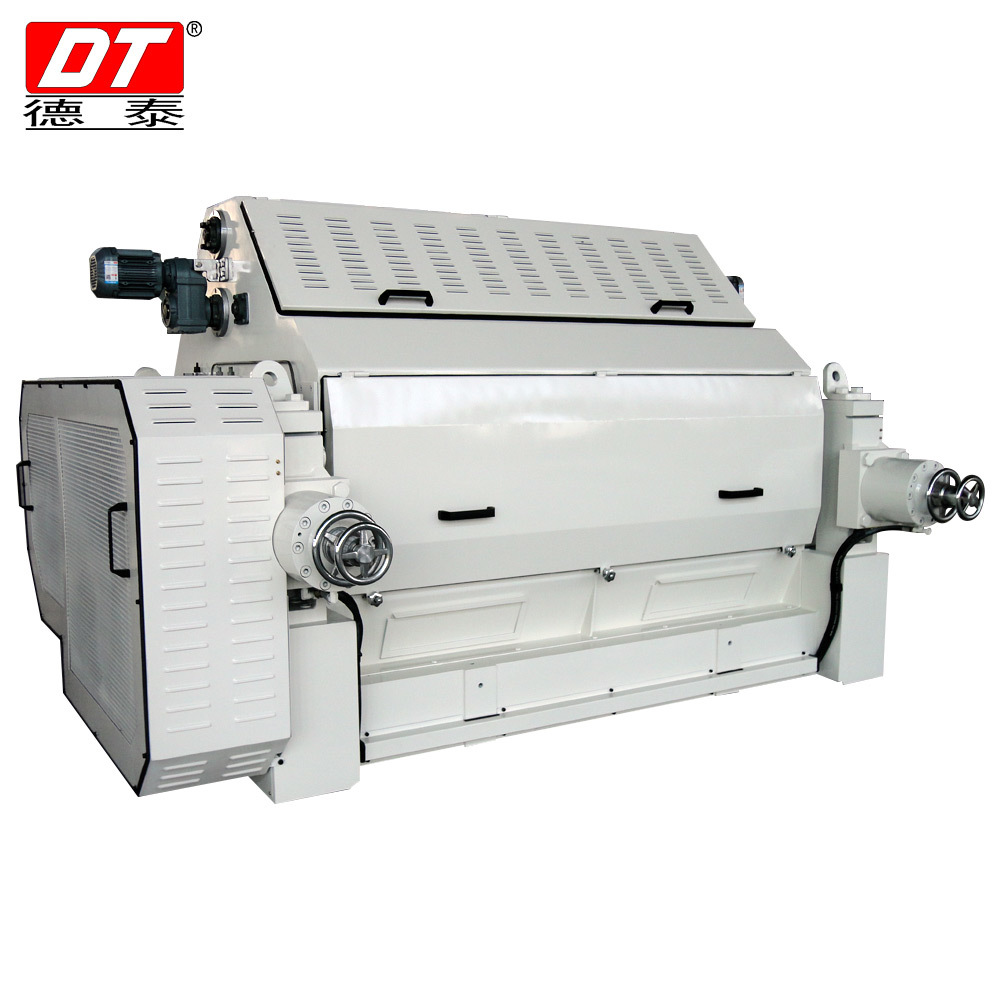

YPG60 corn (oat) tablet press

It is a special processing equipment that extrudes granular materials such as corn and oats into thin slices by rotating two rollers relative to each other, making it conducive to edible digestion.

Technical features:

1. The roll adopts square bearing seat, which is stable, reliable and low noise;

2. Unique design structure, convenient to directly adjust the thickness of the tablet, and has a reliable anti-collision function of the roll;

3. Centrifugal pouring of high alloy rolls, through-shaft assembly process, strong rigidity, heat conduction oil can be filled in the roll body, and good working stability;

4. The electric pump of the hydraulic system adopts intermittent automatic work, the pressure is constant and reliable, and the energy-saving effect is obvious;

5. Humanized design, strong operability, more stable rolling of embryos, long service life;

6. Electrical PLC automatic control;

7. The product has many functions and has independent intellectual property rights.

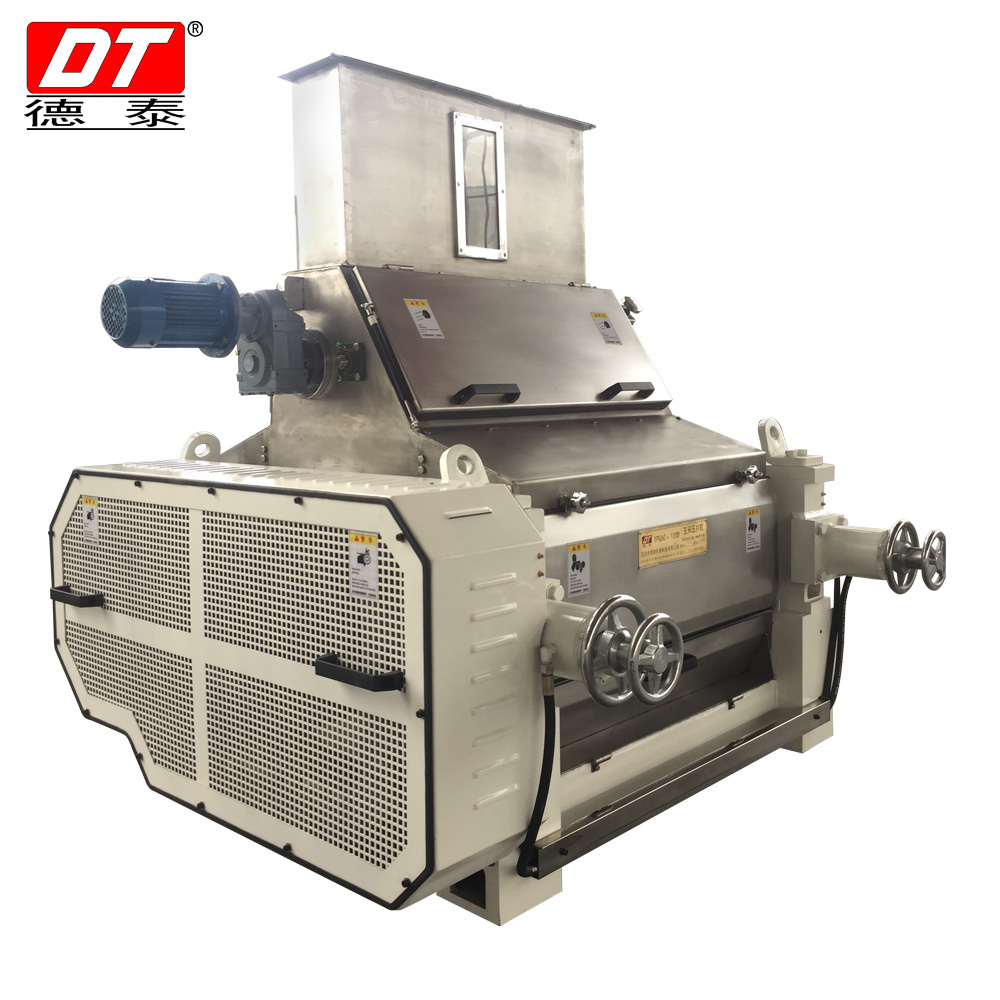

Main technical parameters:

|

Model

|

Processing capacity t/24h

|

Embryo thickness (mm)

|

Equipped power (Kw)

|

Overall dimension(mm)

|

Weight(t)

|

|

YPG60 * 100

|

130-160/45-50

|

~1.2/~0.3

|

22*2+0.55+2.2

|

1912×1669×1834

|

~7

|

|

YPG60 * 125

|

180-220/60-70

|

~1.2/~0.3

|

30*2+0.55+2.2

|

2162×1669×1834

|

~8

|

|

YPG60 * 150

|

260-300/80-90

|

~1.2/~0.3

|

37*2+0.55+2.2

|

2412×1669×1834

|

~9

|

|

Note: 1. In the power items, the main motor power and its quantity, feeding motor and hydraulic station motor power are respectively.

2. The parameter table with "*/*" indicates the technical parameters of processed corn and oats respectively.

3. According to the user's special specifications, it can be customized according to the requirements.

How to scientifically extend the service life of the tablet press? Detai Xiaobian will introduce you in detail.

Before using the tablet press, please repeatedly check the quality of the mold, whether there are missing edges, cracks, deformation, sealing and relaxation, and whether the equipment is in good condition. Check whether the powder of the granular material is dry, and the powder content in the granules should not exceed 10%. If it is not qualified, do not press hard, otherwise it will affect the normal operation and service life of the tablet press and the loss of raw materials.

For the first test run, the indicator needle controlled by the pressure regulator is placed on 6, the powder is poured into the barrel, the test run handwheel is turned by hand, the filling amount and pressure are adjusted at the same time, and gradually increased until the weight and hardness of the tablet meet the requirements of the finished product, then the motor is started first, and then the clutch is started to start production. During the production process, the quality of the tablet must be checked regularly to see if it meets the requirements and, if necessary, to make adjustments.

The choice of speed directly affects the service life of the tablet press. Due to the nature of the raw material, viscosity, size and pressure of the tablet diameter, the purpose of the tablet cannot be uniformly specified. The structure of the tablet press has a stepless variable speed device, and the low speed is suitable for compressing minerals, herbs, large diameters, poor viscosity, etc., as well as materials that are difficult to form quickly. It is fast and suitable for crimping and bonding, has good lubricity and easily molded materials.

Therefore, the user of the tablet press must decide according to the actual situation. Managers must be familiar with the technical performance of the machine, the internal structure, the working principle of the control tablet press and the fact that workplace sounds must not be heard during operation to prevent malfunctions and damage to machine parts to ensure safe production as a premise. In use, always pay attention to whether the sound of the tablet press is always normal, stop when screaming and strange sounds, check and eliminate them, do not use it forcibly.

The above is about the industry sharing of tablet presses, I hope you like it.

Zhuanghe Detai Machinery Manufacturing Co., Ltd. is engaged in grain and oil pretreatment equipment research and development, manufacturing, sales and service as one of the modern production enterprises, the company's main business: billet rolling machine, grain and oil shelling machine, kernel shell separation screen, wire drawing machine, peanut crusher, soybean crusher, cottonseed shelling machine, corn flake press, kernel shell classification screen and other equipment. Find rolling machine manufacturers, shelling machine manufacturers, tablet press manufacturers to find Detai. The company has a large number of outstanding talents in the field of grain and oil machinery and commerce, equipped with various special personnel from technology, production to maintenance. Relying on scientific management system, sophisticated manufacturing equipment, strong technical force and complete testing means, we create high-quality products and provide users with high-quality services.