YPSG40X210 Crushing (peeling) machine_ Crusher_ Peanut crusher_ Soybean crusher

Key

Rolling Mill Series, Crusher Series

Category

Products

Crusher series

Product Details

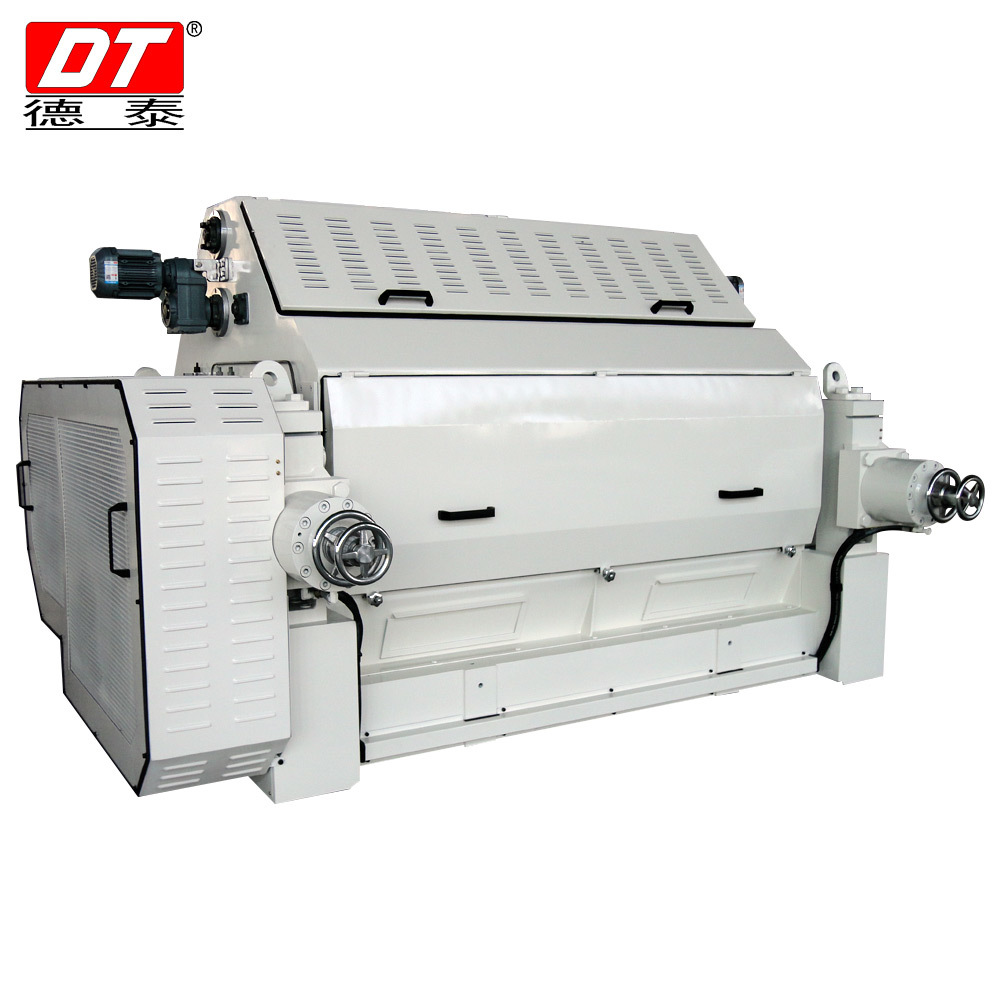

YPSG40 double pair tooth roller crushing (peeling) machine

It is a special equipment that decomposes large (whole) materials into small particles that meet the process requirements through two pairs of opposing tooth rollers rotating relative to each other.

Main structural features:

1. The use of special tooth roller processing, high output, good crushing effect;

2. Centrifugal casting alloy tooth roller, high hardness, good toughness, long service life.

3. Strong operability and easy to use;

4. The clearance of the roller is adjustable, and it has the anti-collision function of the roller to ensure the safe operation of the roll;

5. Multiple functions, stable and reliable performance;

6. Simple structure, convenient repair and maintenance;

7. Fully enclosed protection, and equipped with safety warning signs;

Main technical parameters:

|

Note: For the user's special specifications, it can also be customized according to the requirements.

The crusher is a new model for the pretreatment process in the process of making granular oil from soybeans, peanuts and other granular oils. Through the crushing of granular oil by this machine, the rolling effect can be significantly improved, the quality of the embryo film can be guaranteed, and the oil yield and productivity can be improved. This machine according to market research our company's independent innovation research and development, design four-roller three-mill crusher, with small size, high output, crushing particle size uniform, low power consumption and other advantages, but also has small footprint, compact structure, simple operation, flexible and reliable, convenient maintenance and other characteristics.

The technical advantage

structure of the crusher: the rotation direction adjustment of the root roller reaches four rollers and crushes three times, so that the crushed matter can achieve an effect.

Transmission part: the motor is directly connected to the crushing roller through the elastic coupling, and then the speed is reduced by the gear, so as to realize the differential operation of the fast and slow roller and improve the transmission efficiency.

Fine-tuning part: eliminate the micro-moving gap of the crushing roller through worm gear and lead screw and double nut, and use butterfly spring top tightening technology to ensure the crushing pressure, so that one roller is fixed, and the roll pitch of the three rollers is adjusted arbitrarily;

Tile seat part: the use of building block superimposed arrangement and dovetail guide slide adjustment roller pitch to ensure the stability and reliability of the bearing seat.

Base part: integral frame structure to ensure the smooth operation of the whole machine;

Feeding part: using forced feeding and homogenization device to improve production efficiency;

Magnetic separation part: multi-level magnetic separation device is adopted to avoid the damage of the roll on the impurities of raw materials;

Model part: design, small footprint, easy to operate, beautiful and generous.

Inqiury