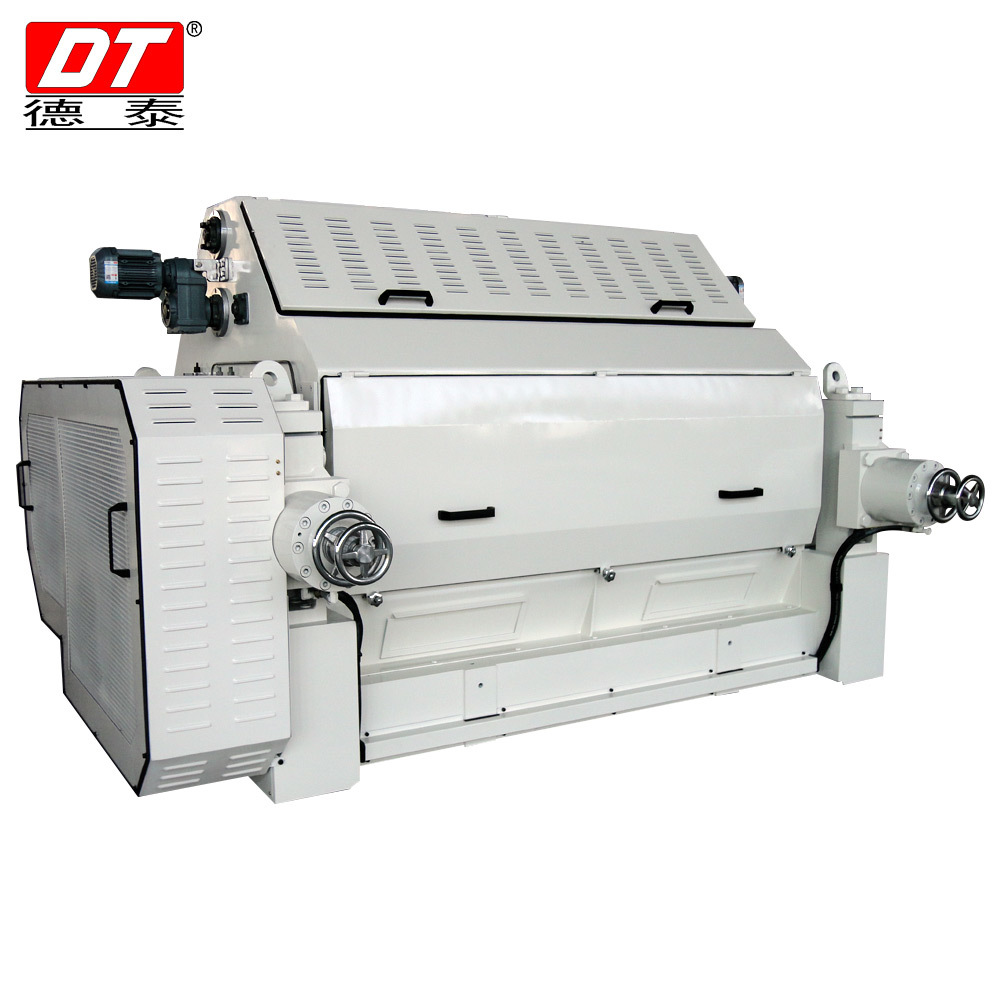

YPSG35X190 Crushing (peeling) machine_ Crusher_ Soybean crusher_ Peanut crusher

Key

Rolling Mill Series, Crusher Series

Category

Crusher series

Product Details

YPSG35 double pair tooth roller crushing (peeling) machine

It is a special equipment that separates large (whole) materials into small particles that meet the process requirements through two pairs of opposing tooth rollers rotating relative to each other.

High-tech features:

the whole machine adopts stand-alone drive, square structure bearing seat, and is convenient to realize synchronous adjustment of roller clearance; Has independent intellectual property rights. (Patent No.: ZL201220182528.1) At the same time, it also has:

1. Special tooth roller processing, high output and good crushing effect;

2. It has the function of anti-collision of rollers;

3. Multiple functions, stable and reliable performance;

4. Humanized design, strong operability, easy to use;

5. Centralized lubrication, convenient maintenance and maintenance;

6. Fully enclosed protection, and equipped with safety warning signs;

7. Long service life;

Main technical parameters:

|

Advantages of crusher equipment:

1. Fully enclosed structure, shell, front and rear (upper and lower) door panels and protective cover using high-quality carbon steel plate, front and rear and both sides with heat dissipation net;

2. The frame supporting the roller is made of cast steel material, which is processed and finished by aging to ensure sufficient strength and rigidity, so as to ensure the stability and reliability of the tooth roller operation, and ensure the output and life.

3. The crushing roller bearing adopts domestic brand products, which have low noise, stable operation and long service life.

4. The pulley adopts the design of the tensioning sleeve, which is easy to disassemble;

5. The moving and fixed crushing rollers adopt standard independent bearing supports, which are quick to disassemble and maintain, and convenient to operate and maintain;

6. Feeding device: the material is evenly and continuously fed into the tooth roller for crushing.

7. Material blocking and magnetic separation device: the advanced four-link mechanism is adopted to adjust the amount of material and clean up the debris on the magnet, which is very convenient;

8. Distance adjustment device: the turbine worm digitally adjusts the roll spacing, so that the moving roller and the fixed roller can never touch;

9. Lubrication system: the lubrication port of the tooth roller bearing of this machine is outside the protective cover, and it is very convenient to adopt centralized lubrication;

10. The machine adopts two pairs of rollers above and below to work, and the main drive is equipped with a Siemens motor 90KW;

11. No electric control cabinet.

Inqiury