Reasons and countermeasures for wire breakage in wire drawing machines

When using dust drawing machine equipment, it is inevitable to encounter problems such as broken wires, and there are many reasons for this problem. To help you solve this problem better, we will analyze the reasons for you and make some suggestions. Let's take a look at the specifics.

24

2021

/

03

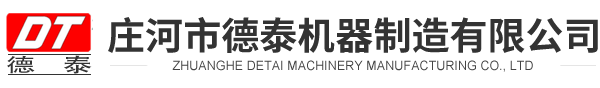

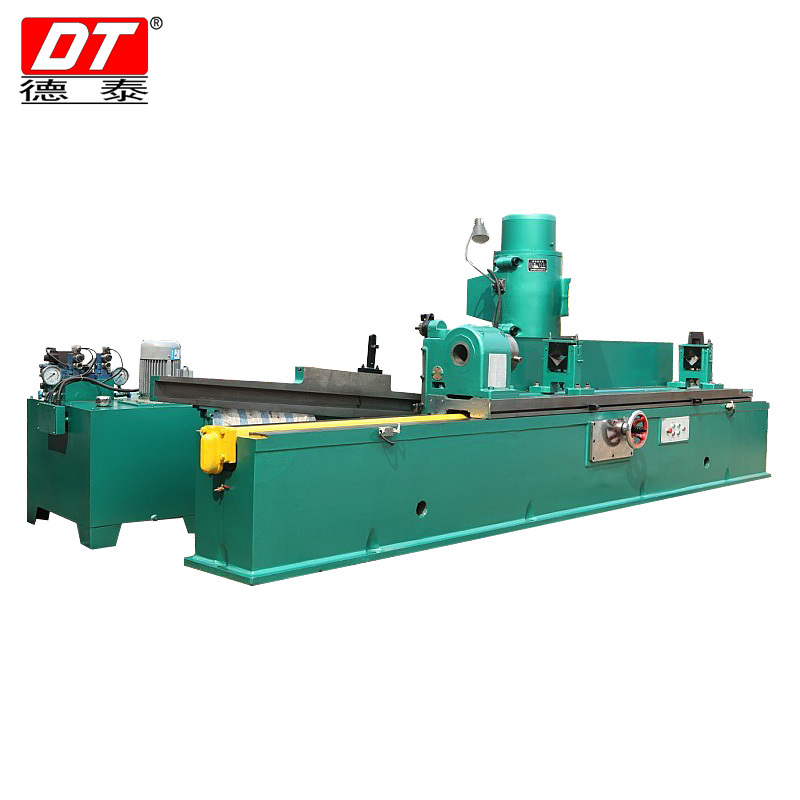

Operation requirements and maintenance of wire drawing machine

Before operating the wire drawing machine, the operator must carefully read the drawings and related technical data, and understand and master them. When machining, it is necessary to correctly select and confirm the drawing direction, drawing surface, etc., and operate according to the rules. It is also necessary to maintain the appearance of the workpiece to prevent it from being scratched and to avoid deterioration.

08

2020

/

12

Heating method and speed control system of wire drawing machine

The wire drawing machine is used for ordinary plastic wire drawing machine with high requirements for wire drawing. The entire system is more complex, and the control equipment requires coordination between the various motors. There are many ways to heat the wire drawing machine, some use resistance wire heating, some use electromagnetic heating.

11

2020

/

12

Control mode of wire drawing machine and energy-saving measures for power consumption

The wire drawing machine process is a surface treatment technology for workpieces. A surface treatment method is to achieve a decorative effect by forming a line on the surface of the workpiece through a wire drawing machine. Since the wire drawing treatment on the surface can reflect the texture of the metal material, the automatic wire drawing machine has been adopted by more and more enterprises.

21

2021

/

04

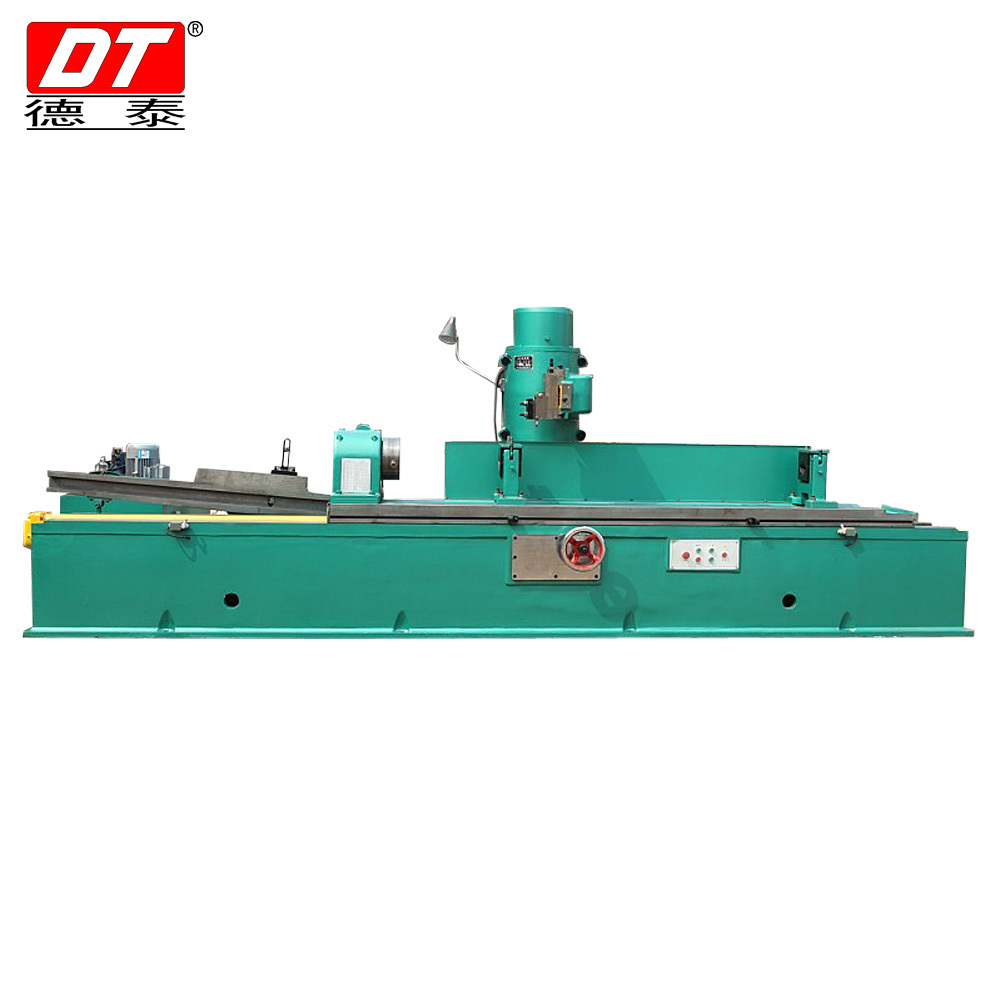

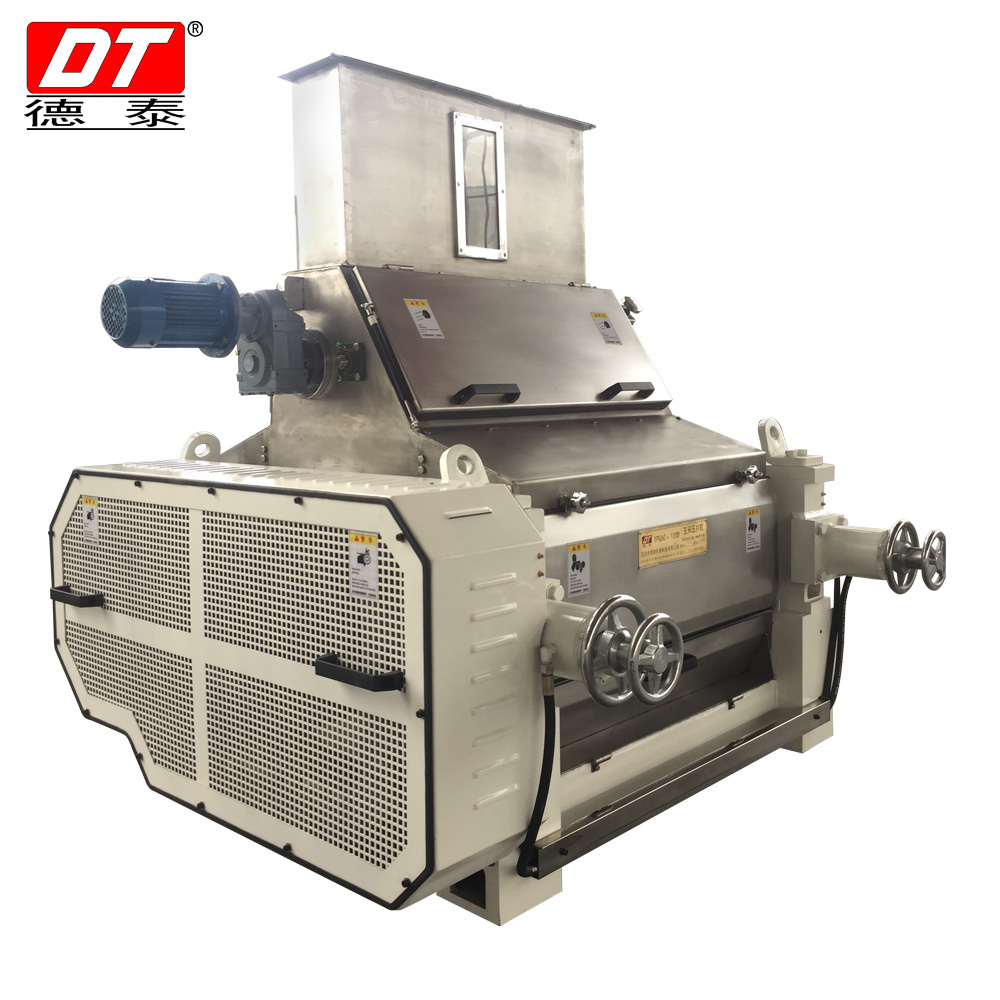

Manufacturer of the embryo rolling machine: Characteristics of the embryo rolling machine

Rolling mill manufacturers are the main equipment for pretreatment when extracting oil from soybeans, peanuts, rapeseed and other oil plants on a large scale in the oleochemical and food industries. Its performance directly affects the process and production schedule of the oil plant. The quality of rolled billets directly affects refined oil.

17

2020

/

12

It is very important to use an appropriate shockproof foundation for the crusher

It is very important that the crusher adopts a proper anti-vibration foundation, and the anti-vibration measures of the crusher are also very necessary. When the crusher must be placed on the floor, it is necessary to design the foundation, take measures to isolate vibrations and check the calculation results. To avoid the possibility of vibration of the crusher.

04

2021

/

01

How to extend the service life of the tablet press?

Before using the tablet press, please repeatedly check the quality of the mold, whether there are missing edges, cracks, deformation, sealing and relaxation, and whether the equipment is in good condition. Check whether the powder of the granular material is dry, and the powder content in the granules should not exceed 10%. If it is not qualified, do not press hard, otherwise it will affect the normal operation and service life of the tablet press and the loss of raw materials.

18

2021

/

01

Technical advantages and equipment advantages of crushers

The crusher is a new model for the pretreatment process in the process of making granular oil from soybeans, peanuts and other granular oils. Through the crushing of granular oil by this machine, the rolling effect can be significantly improved, the quality of the embryo film can be guaranteed, and the oil yield and productivity can be improved. This machine according to market research our company's independent innovation research and development, design four-roller three-mill crusher, with small size, high output, crushing particle size uniform, low power consumption and other advantages, but also has small footprint, compact structure, simple operation, flexible and reliable, convenient maintenance and other characteristics.

08

2021

/

06