Billet rolling machine, crusher, shelling machine, blade shelling machine, separation screen

Zhuanghe Detai Machinery Manufacturing Co., Ltd., founded in 2006, is engaged in grain and oil pretreatment equipment research and development, manufacturing, sales and service as one of the modern production enterprises, located in Zhuanghe City, the coast of the Yellow Sea in the eastern part of the Liaodong Peninsula, moved into the new factory in 2016, covering an area of nearly 30000,8000 square meters, modern production and processing workshop of nearly <>,<> square meters. The company has a large number of outstanding talents in the field of grain and oil machinery and commerce, equipped with various special personnel from technology, production to maintenance, which is the fundamental guarantee for our stability and development.

23

2020

/

06

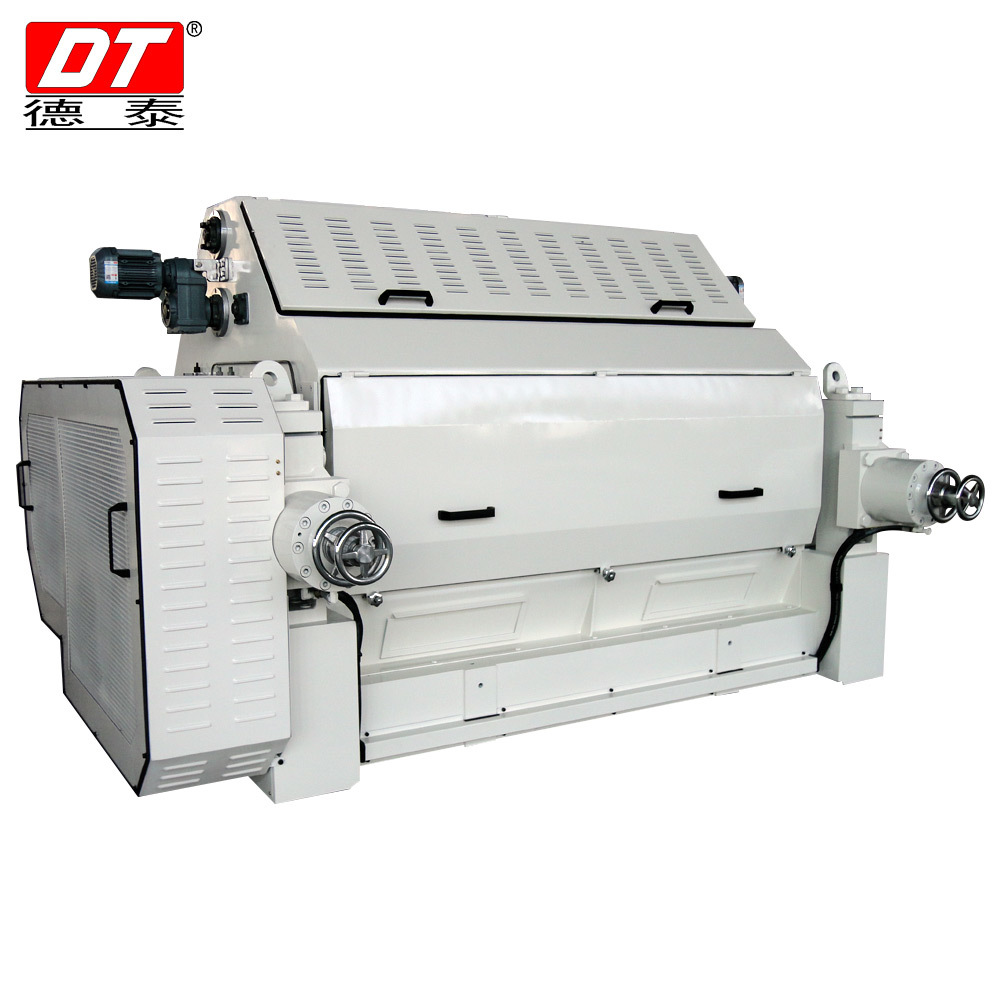

YYPYFP2X81X220D anti-collision hydraulic billet mill High-tech features: 1. The roll control adopts square bearing seat, which is more stable and reliable in operation and makes the noise lower; 2. Unique design structure, convenient to directly adjust the thickness of the embryo, and has a reliable anti-collision function of the roll; 3. The homogenizing roller and the tooth roller can be used for composite feeding to ensure that the feeding is more uniform, and the frequency conversion can control the feeding amount;

12

2020

/

09

Correct operation steps for grain and oil shelling machine

The fixed installation of the machine must be kept at the front, back, left and right levels (judging according to the fluidity of peanut kernels), otherwise there will be a mixed phenomenon of outlet kernels. The method of leveling is: the side with more peanuts indicates that this side is lower, and the wheels on this side should be slightly lifted with a sack (the new environmental machine should be adjusted in the opposite direction); If the outlet of a small fruit is mixed with nuts, it means that the edge is too low. If it is low, the guide wheel should be raised.

18

2020

/

11

Maintenance of Grain and Oil Shelling Machine

Grain and oil shelling machine is used as a machine to crush and peel oilseed and nut shells. It is composed of feeding, shell breaking, shell and kernel separation, discharging, adjustment and other mechanisms. According to the working principle of the shell breaking mechanism, it can be divided into disc type, cutterhead type, knife cage type, centrifugal type, roller type, etc. The material is crushed by grinding, shearing, squeezing or impacting, and then the shell and kernel separation mechanism consisting of a fan and sieve is removed from the shell to obtain pure nuts.

20

2020

/

11

Manufacturer of the embryo rolling machine: Structure description of the embryo rolling machine

The mill produced by the mill manufacturer is mainly made of two or several rolls (high nickel-chromium-molybdenum alloy) rotating in opposite directions. When the oil (soybeans, peanuts, cottonseed, etc.) passes through the middle of the two rollers, the embryo is formed by an instantaneous extrusion force. Crude oil is pushed out, then refined and leached to form a finished cooking oil. It is a typical extrusion equipment.

24

2020

/

11

Manufacturer of billet rolling machine: Introduction to billet rolling machine equipment

Shell: The shell and the protective cover on both sides are coated with carbon steel plate, and the upper and lower door panels are coated with aluminum plate. Movable door panel: The movable door panel and the sample inlet are equipped with sealing strips, which are easy to open or disassemble; There is a sampling port or door under the fuselage to check the effect of the rolling stock for adjustment.

26

2020

/

11

Characteristics of Kernel Shell Separation Sieve

Kernel-shell separation sieve is a screening machine that separates core-shell mixtures after dehulling. Separation is carried out by using different proportions of kernels and shells after peeling. It is mainly used for the separation of cottonseed kernels in oil and fat processing plants, and also for the separation of raw materials such as peanuts and sunflower seeds after peeling.

30

2020

/

11

Manufacturer of peanut shelling machine: Operating requirements for peanut shelling machine

The peanut shelling machine produced by the shelling machine manufacturer brings convenience to farmers, but many farmers who are new to this machine still do not know much about it. It is inevitable that there will be some improper operations during use, which will not only increase the performance loss of the machine, but also reduce the working efficiency of the machine to a certain extent. In fact, as long as two requirements are met when using, the above problems can be avoided. Let's take a look at these two requirements!

03

2020

/

12